Aluminium extrusion is also referred to as ‘aluminium frames’. It involves bulk plastic deformation procedure. An aluminium billet is first preheated to a given temperature, considered to be below material melting point. Aluminium Profile in Chennai is to facilitate plastic material flow. Heated billet gets forced through the specially designed tooling die to shape so as to convert the billet to corresponding profile cross-section. Industrial extrusion procedure is considered to be analogous to culinary technique that is used for creating different forms of pasta. It is also referred to as a technique to create different types of shapes in toys for children.

Aluminium Profile in Chennai: Know the advantages

Aluminium is a commonly used material used in shape profiles and extrusions. This is due to the mechanical features it possesses, thus making it ideal for shaping as well as creating metals from the billet sections. Aluminium’s high malleability means, it is possible to shape easily this metal into different sections without having to expend energy on forming or tooling process. Moreover, its melting point is half of what is noticed in ordinary steel. This means, aluminium extrusion procedure tends to have low energy footprint that translates into reduced manufacturing costs and low tooling. Besides this, it also possesses enhanced strength-weight ratio, thereby being the top choice for many industrial applications. But to derive the benefits, you need to consider buying only from the top Aluminium Profile Manufacturer in Chennai like National Aluminium.

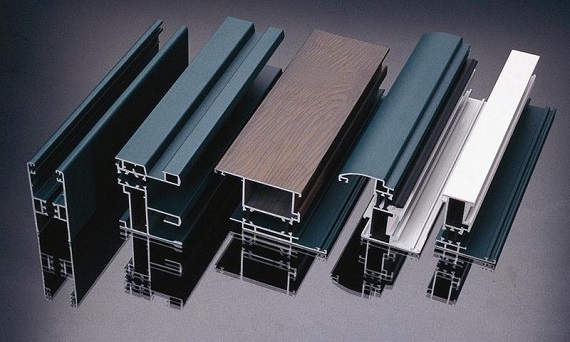

Aluminium Profile Types

There are created different types of intricate extrusion profiles of this metal at varying thickness. Such profiles tend to feature wide range of void spaces that is necessary for end-use applications. Internal voices are present of wide range to facilitate different types of automation applications. It also helps satisfy performance weight requirements. When aluminium profile is concerned, the common type available is hollow beam profile. This variation is actually a square profile. Also are available other profile types like L-shaped, single radius and triangular profile.

Surface types

Being considered to be the by-product of the extrusion procedure, at times, there are present barely small visible lines on the profile surface. It is due to extrusion tooling. These lines can be eliminated with additional surface treatments. You may perform secondary surface-processing operations like face milling after major extrusion creation process to enhance profile section surface finish. It is possible to specify such processing operations to enhance surface geometry to enhance part profile. This is done by reducing significantly the extruded profile’s overall surface roughness. Such treatments are mentioned in the applications especially those that need precise parts positioning or tight controlling of mating surfaces. Carrying out surface treatments by Aluminium Profile in Chennai can improve corrosion resistance. This, in turn, helps the extrusions to derive electrical insulation or enhance profile hardness.

Profile sections & it’s different uses

Industrial automation applications such as automated motion applications especially on process lines including manufacturing industries consider using aluminium profiles. The reason for its increasing demand is because although lightweight it is strong, durable and handled effortlessly. It can also be formed into different configurations as required by automation structure.

Getting hold of the best Aluminium Profile Manufacturer in Chennai like National Aluminium can help save money on purchase.